[ad_1]

28

Sep ’21

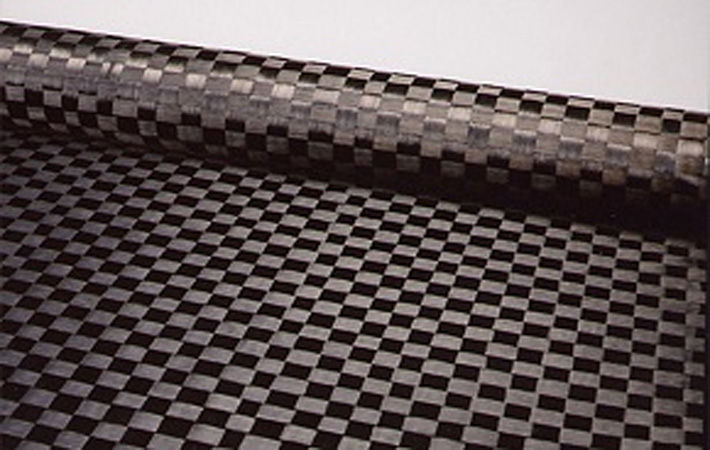

Pic: Mitsubishi Chemical Corporation

Mitsubishi Chemical and Mitsubishi Chemical Advanced Materials Japan (MCAM) have announced the development of a thermoplastic composite material (FRTP) which offers flame retardancy, high production performance, and recyclability. Mitsubishi Chemical is a chemical producer, supplying different sectors from automotive and electronics to medical and sport.

Today, electric vehicles (EVs) are widely being developed with zero emissions to combat climate change. Two fundamental aspects of the EV battery systems are the requirement of higher fire resistance for passenger’s safety and utilising lightweight materials to further save energy. Conventional technologies have often applied thermoset plastic composites, which have flame retardancy and are lightweight. However, low recyclability and less production performance are often considered issues, Mitsubishi said in a media statement.

Mitsubishi and MCAM have together solved these issues in the development of FRTP by bring together our technology about battery systems and optimizing our unique fibres and thermoplastic resin compositions and achieving fire resistance that withstands more than five minutes of a flame over 1000? in our experiment. Mitsubishi and MCAM have already commenced sample work for some customers, and aim to develop new applications such as battery enclosures.

Mitsubishi Chemical and Mitsubishi Chemical Advanced Materials Japan (MCAM) have announced the development of a thermoplastic composite material (FRTP) which offers flame retardancy, high production performance, and recyclability. Mitsubishi Chemical is a chemical producer, supplying different sectors from automotive and electronics to medical and sport.

Mitsubishi is focused on continually developing multiple new composite solutions for our customers to replace conventional materials, and will continue to actively develop our business by providing optimal solutions in a timely manner.

Fibre2Fashion News Desk (GK)

[ad_2]

Source link